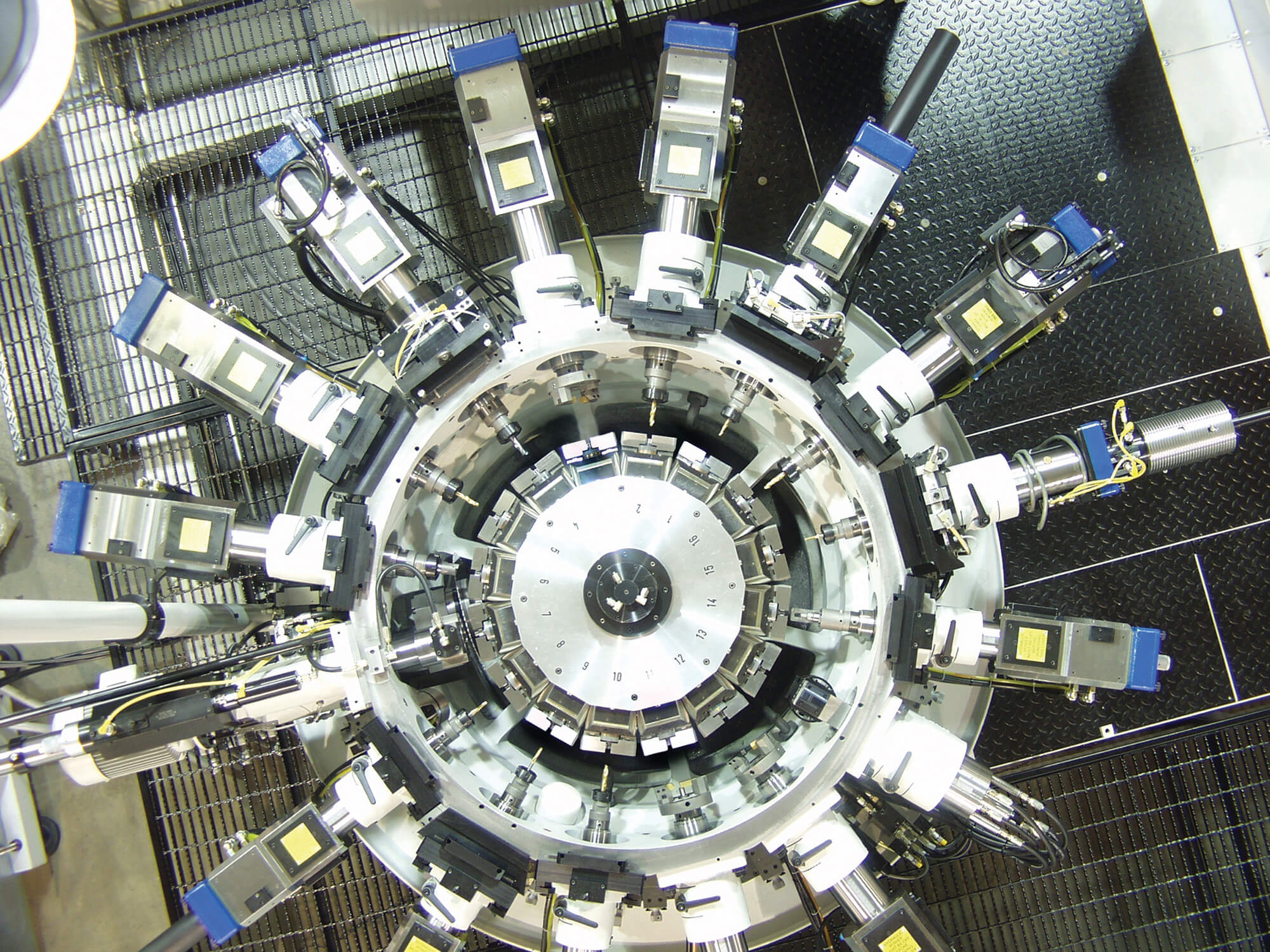

Rotary Transfer Precision Machining

We consider Hydromat Rotary Transfer Machines to be our #1 solution for high volume production parts from coil, bar stock, extrusions, castings or forgings and eliminating the need for secondary operations. Our 20 Hydromats feature up to 24 machining stations allowing for customized applications and cycle times are as low as 3 seconds, less than the same amount of time required to feed barstock or to load a blank into CNC machinery.

Machining Technologies is a full service machining facility also encompassing; CNC milling and turning; CNC Swiss screw machining; Escomatic and Wire EDM. Each specialty is supported by our own engineering, processes, and assembly services.

- Capacity to bar feed round, square, hex and other shapes.

- In-house Process Engineering means faster turnaround time for new parts and greater flexibility when your parts change.

- State-of-the-art statistical inspection sampling ensures you receive the highest quality parts with the most reliability.

- Customer managed inventories allow you to take delivery of parts when you need them.

- Logistical support for plating, heat treating and other secondary operations assures you of quality finished parts.