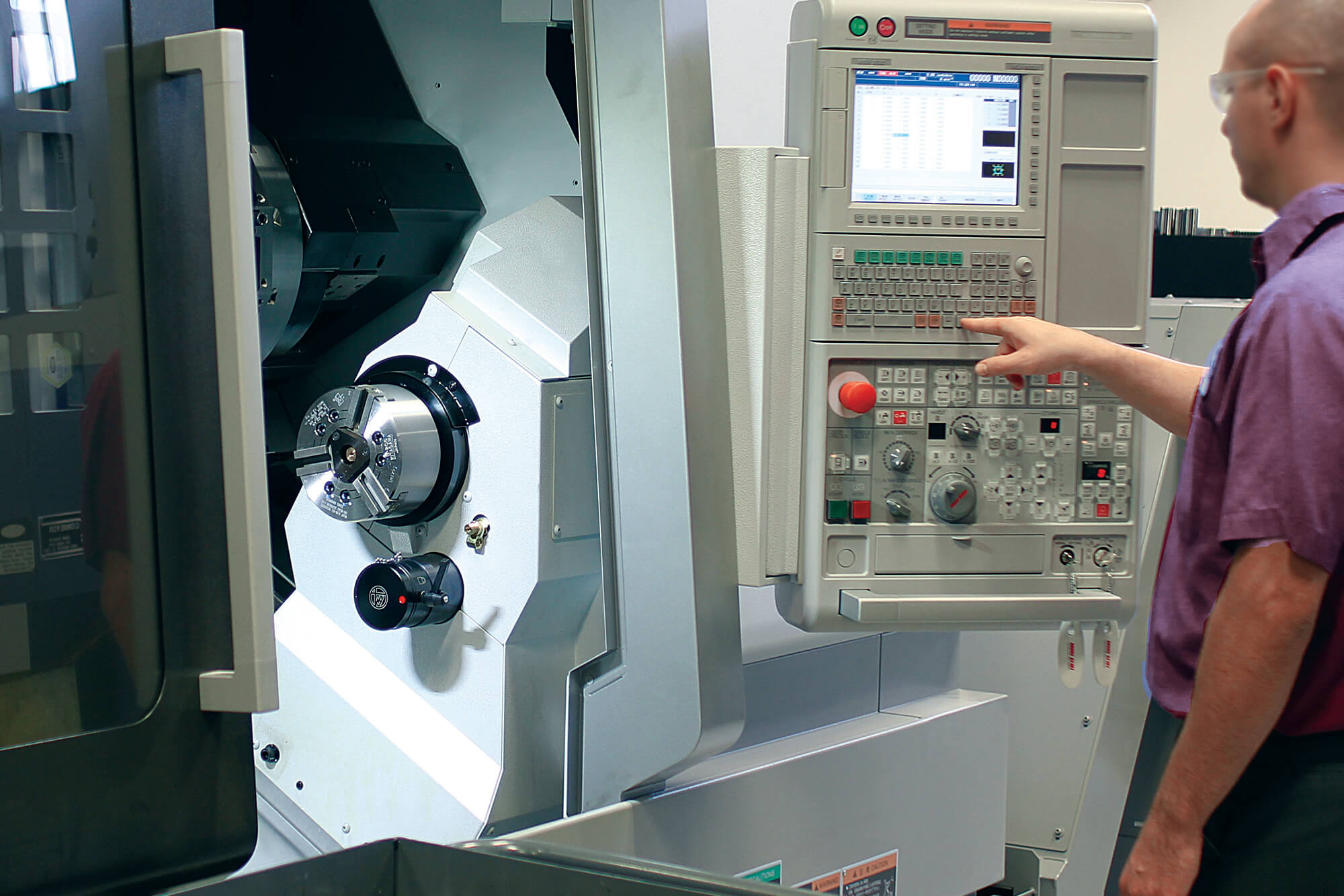

CNC Milling and Turning

For larger components, Machining Technologies professionals are well equipped with state of the art CNC machines to heighten productivity while significantly reducing cost. Their flexible work holding options handle a broad range of part and order sizes for super quick setups, efficient changeover ensure timely production of your prototypes and low volume runs.

Our trained and experienced staff meet your toughest requirements and are experts in high speed metal removal, and are fully equipped and trained to handle multiple orders with precision, maximum throughput, and immediate delivery. We offer expertise in CNC Prototyping in all metals and high performance materials. Computer-aided-manufacturing, regulatory inspection, and other key services, accommodating a wide range of part sizes and quantities.

CNC Turning

- Capacity to bar feed up to 3 1/2″ diameter material

- Chuck work up to 24″ diameter material

- Experience machining stainless steel, aluminum, brass, steel, aircraft and high temperature alloys, and plastics

- Large tooling capacity to machine complex parts in a single setup

- Prototype production as well as small and medium quantity production runs available

CNC Milling

- Experience milling Hastelloy, Inconel, titanium and other exotic alloys

- High pressure coolant for higher cutting speeds and better chip control

- CAT 40 tool holders and large tool magazines

- Mastercam software for complex tool paths

- 4th axis milling capability